Corrosion In Water Systems

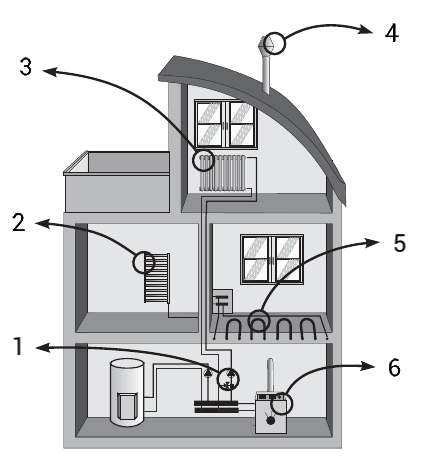

Early underfloor heating systems used plastic pipes that were permeable to oxygen. Technology has since advanced to the point where it is now possible to produce underfloor heating pipes that are practically diffusion proof. Valves, threaded joints, circulating pumps, regulators, automatic bleed devices and faulty expansion tanks, however, are still potentially important sources of oxygen uptake. Oxygen diffusing into the heating water, too low a pH value and raised electrical conductivity of the system water can all lead to corrosion and blockage of the heating system from corrosion products.

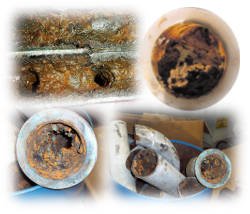

1 - Blockages in control valves and pumps

2 - Holes in radiators leading to water damage

3 - Noisy circulation from gases produced by corrosion

4 - Increased power consumption from irregular heat distribution

5 - Underfloor heating pipes clogged with corrosion product

6 - Boiler corroded through

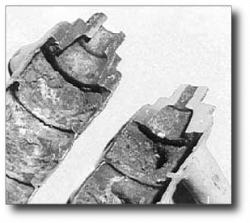

Radiator element with sludge

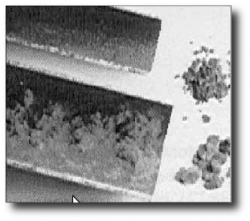

Corrosion particles Rust (Fe203),

Magnetite (Fe304)

Corrosion holes in wall of heating boiler

The ELYSATOR offers a modern clean and proven alternative to problem of corrosion control in hot and cold water systems from large industrial systems to small domestic units. The ELYSATOR system is fitted to such diverse applications as the Swedish Nuclear Power generator to the new Oslo airport where over 40 units are installed. It has also been supplied to many thousands of buildings large and small to provide protection for the heating and chill water systems.