Protector P5 Micro

| Max system volume: | 10 m3 |

| Max flow: | 15 l/min |

| Max temperature: | 95°C |

| Tank volume: | 20L |

PROTECTOR is a combined water heater and stainless steel filter, designed for closed heating and cooling systems. It will neutralize the water as well as remove sludge and particles to maintain the best efficiency.

Each filter contains Neodynium magnets to retain ferrous particles, Magnesium anodes to consume oxygen and increase the pH value, and a stainless steel filter element (110μm or 55μm) or bag filter (various micron sizes, down to 1 μm) to filtrate the water and remove any suspended solids. The two filter types are entirely interchangeable.

Features

- Particle Filtration

- Magnetic Protection

- Corrosion Prevention

Downloads

Material of vessel: stainless steel.

Insulation: Armaflex.

Installation. In closed systems, typical installation will be in partial flow, but it can also be installed in main stream and built up in modules for larger plants. This provides a bottle cap and easy installation for operation and maintenance.

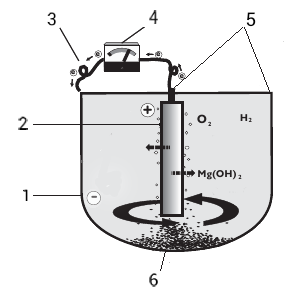

The function of the Elysator is based on the anodic/cathodic principle, i.e., letting a less noble metal (magnesium) be sacrificed (corroded)instead of the system itself, related to galvanic series/elements. During the process the oxygen in the water will be absorbed creating H2O and magnesium hydroxide. When the Elysator is installed, the entire system will be protected from corrosion. Even aluminium and aluminium alloys are protected.

WHAT HAPPENS?

Dilution of magnesium

Anode:

Mg(s) → Mg2+(aq) + 2e-

Cathode:

½O2 + H2O + 2e- → 2OH-

Total reaction:

Mg(s) + ½O2 + H2O → Mg (OH)2

1 - Cathode

2 - Anode

3 - Folow of electrons

4 - Meter/Check

5 - Potential difference for steel/magnesium

6 - Impurities filtered out by suitable circulation

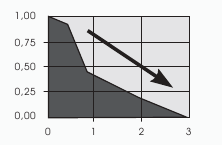

Dissolved oxygen O2

mg/l

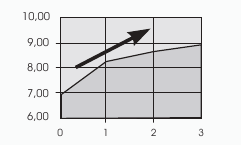

pH value

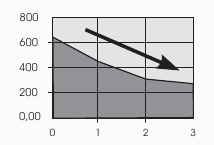

Electrical conductivity

μS/cm

ADVANTAGES

- No chemicals

- Minimum maintenance

- Self regulating

- Kills and prevents growth of bacteria

- Savings in cost of chemicals and prevention of corrosion related failures

- Fast "Pay back"

- Improved water quality due to sludge and deposits removal

- Environmentally safe and meets ISO 1400 requirements

ILLUSTRATION

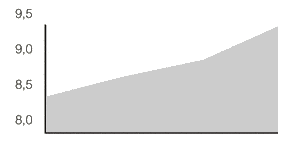

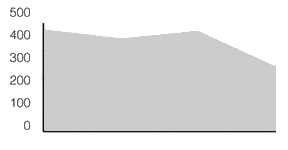

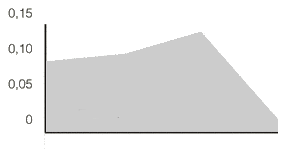

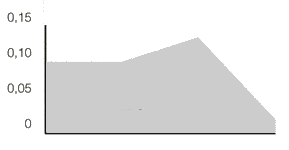

Typical values measured during the first month after installing the Elysator. On the engine cooling system of a 17 year old ship.

pH value

Conductivity

Iron

Copper

1. pH - Value

Corrosion is also due to acidic water. (low pH value, evaporated water normally holds a pH at aprox.5.5) The ELYSATOR system automatically regulates the pH value to approx. 9.5 (This is caused by splitting of magnesium hydroxide from the anodes).

2. Electrical Conductivity

100% pure water is non-conducting. It is important that electrical conductivity is kept as low as possible in order to avoid galvanic corrosion as well as to reduce the stress on pumps, gaskets, heat exchangers etc. The efficiency of the ELYSATOR is proportional to the conductivity, which means that the ELYSATOR is regulating itself in accordance to the condition in the water.

3. Deposits

Major parts of the deposits are oxides of Fe (iron) and Cu (copper). They are both a result of corrosion due to an oxygen surplus, low pH or a galvanic current. The amount of dissolved copper is a measure for the ongoing corrosion process in your system. Through the ELYSATOR the water will be neutralised and metallic surfaces stabilised. Corrosion is therefore eliminated and the water stays clear, clean and without sediments. The deposit sludge is simply removed by daily draining of the Elysator.